About us

Welcome to Equigrow,

A peat free, 100% natural, family run compost business operating at Cattlegate farm, in Enfield. We do our best to give you the finest quality compost you and your garden are looking for. Incorporated in 2011, Equigrow has access to 2000 acres of land which is shared with the UK’s and Northern Europe’s biggest herb production company. A leader of fertilization, Equigrow has risen through the ranks and become a widely popular choice for keen gardeners and bulk buyers for commercial use. All products made by Equigrow are PEAT FREE, giving us the edge over our competitors.

Feed your garden the natural way… PEAT FREE!!

Mulch

When people think of mulch, they usually have something in their mind that looks like shredded up trees. But, did you know that mulch is any material, organic or not, that is placed over the surface of the soil to conserve moisture, suppresses weeds, keep soil temperature and moisture normal, or make the garden more attractive.

How we make our soil conditioner

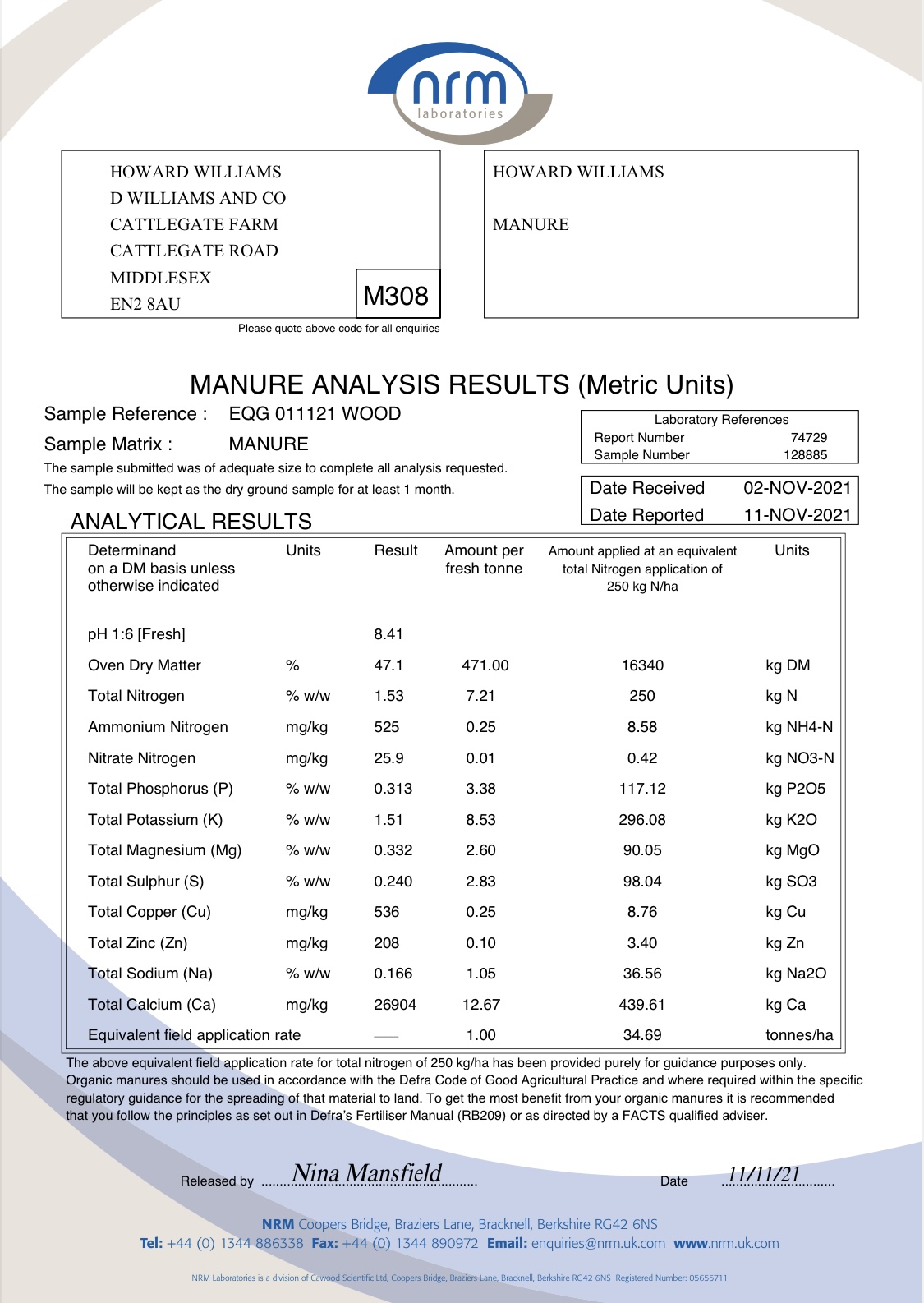

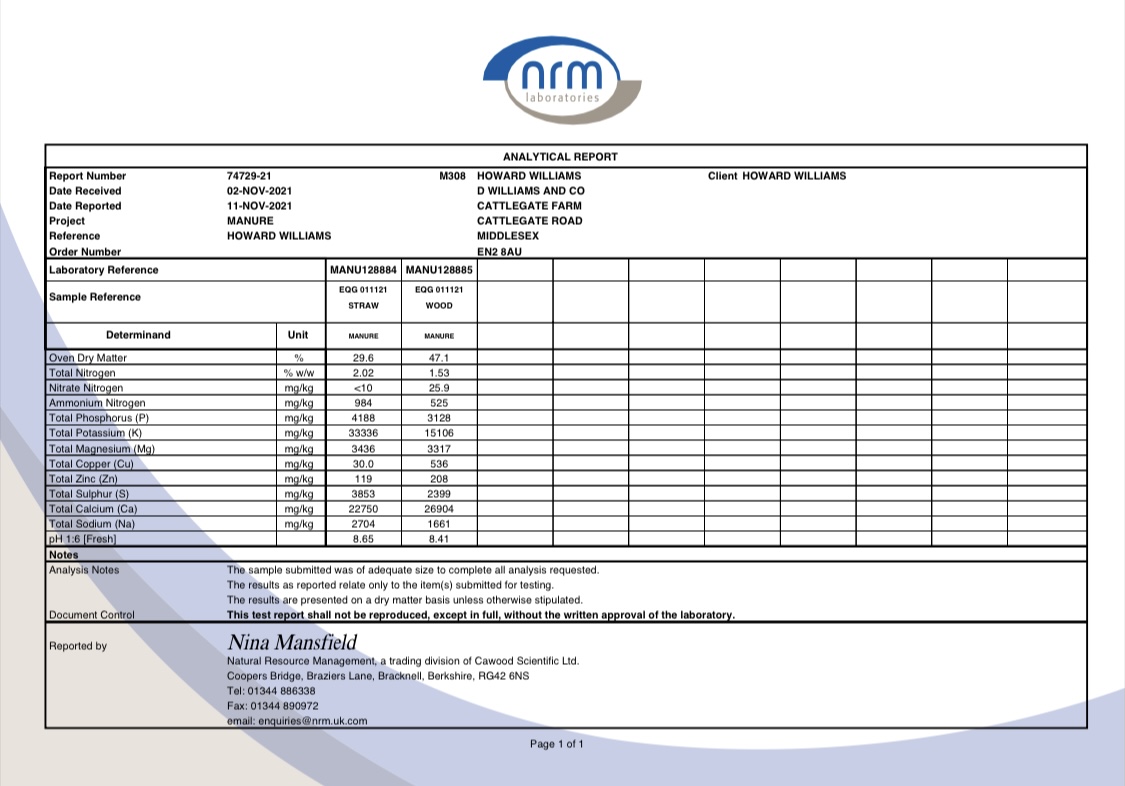

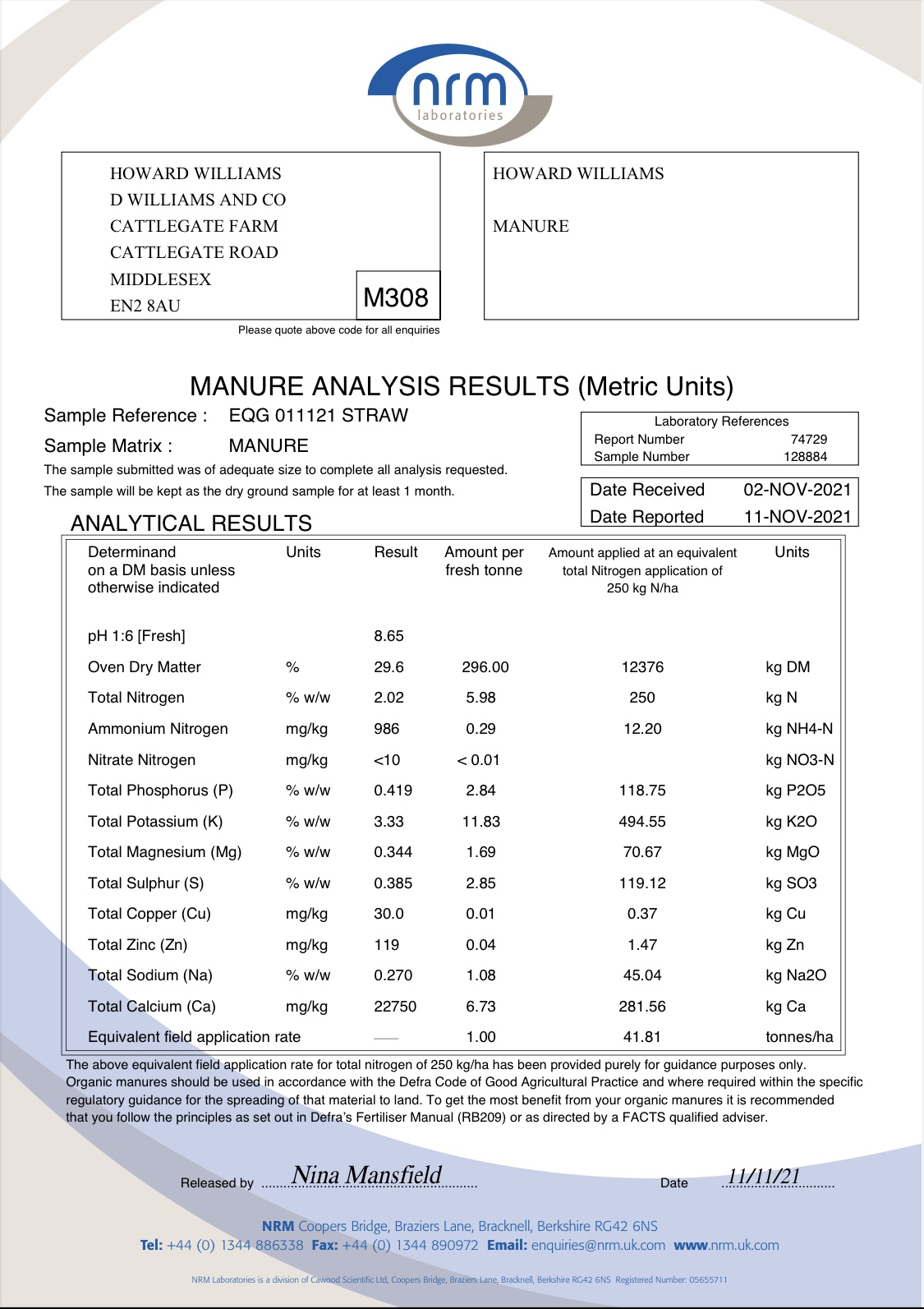

Our soil conditioner consists of horse manure, straw, and a minimal amount of wood shavings, which helps to aerate the compost. The manure is collected daily from stable yards in the local area and brought to our farm where it is processed and turned regularly, allowing oxygen to permeate through. This creates heat, which kills most pathogens and weed seeds.

After roughly a month, the manure is put through a shredder to help break it down, therefore speeding up the process. For the next three months, the manure is continued to be turned and lastly it is screened to 40mm and ready for bagging or distribution.

How we make our fertile mulch

Our fertile mulch goes through a similar process as the soil conditioner and consists predominantly of horse manure and wood shavings. The manure is heaped up and turned at regular intervals until it is dark brown in colour, at which time it is ready for bagging or distribution. This process takes approximately six months.

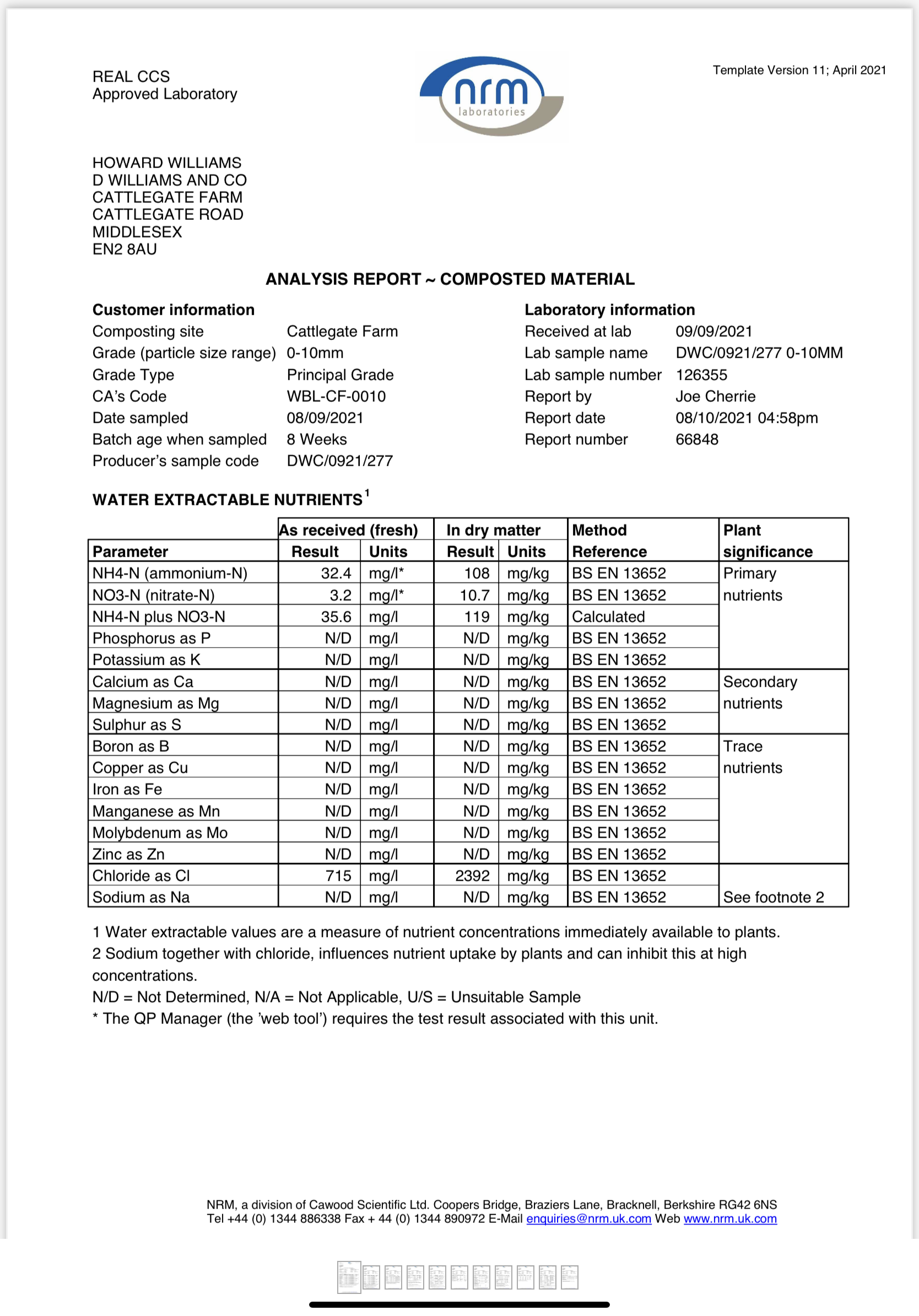

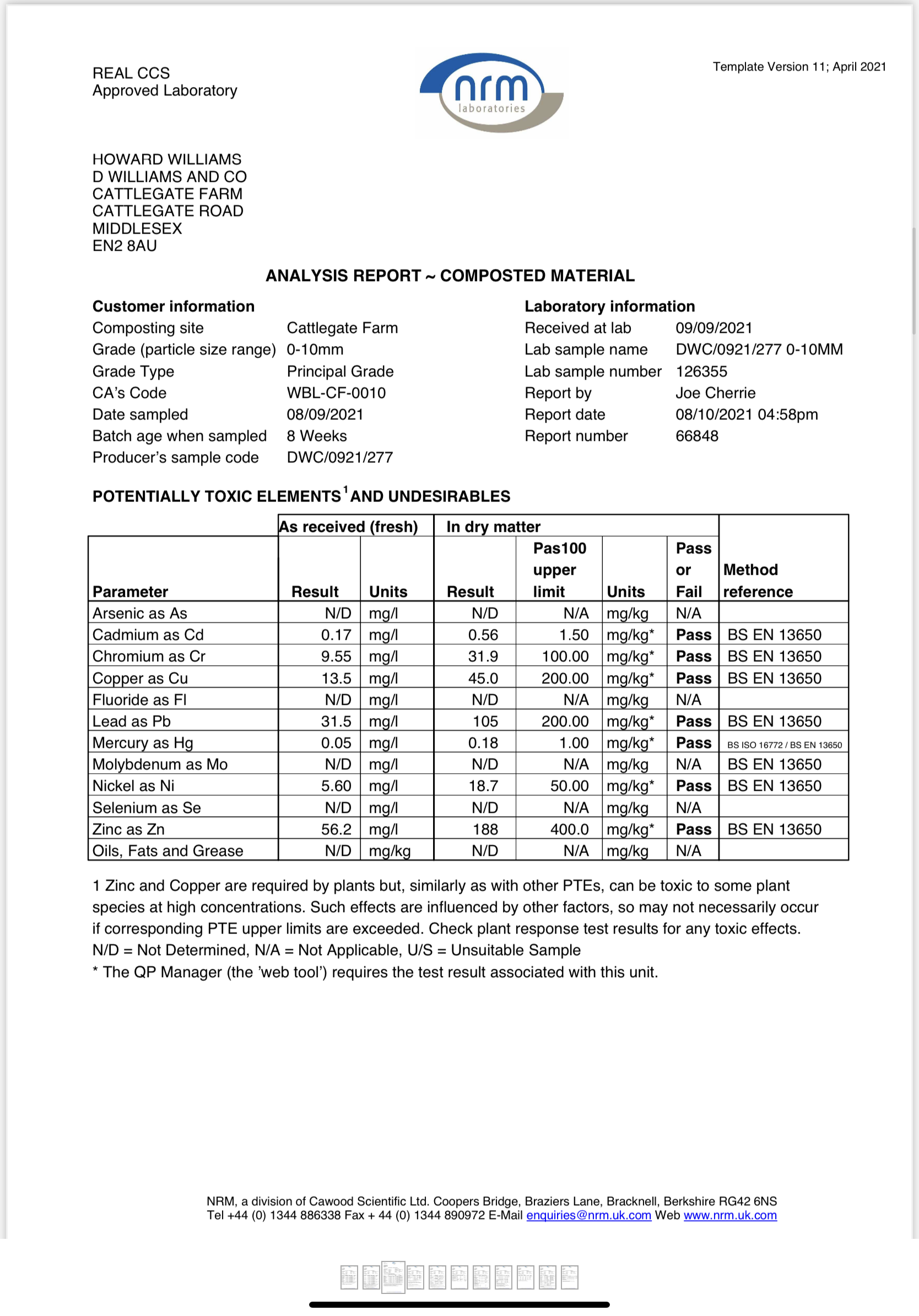

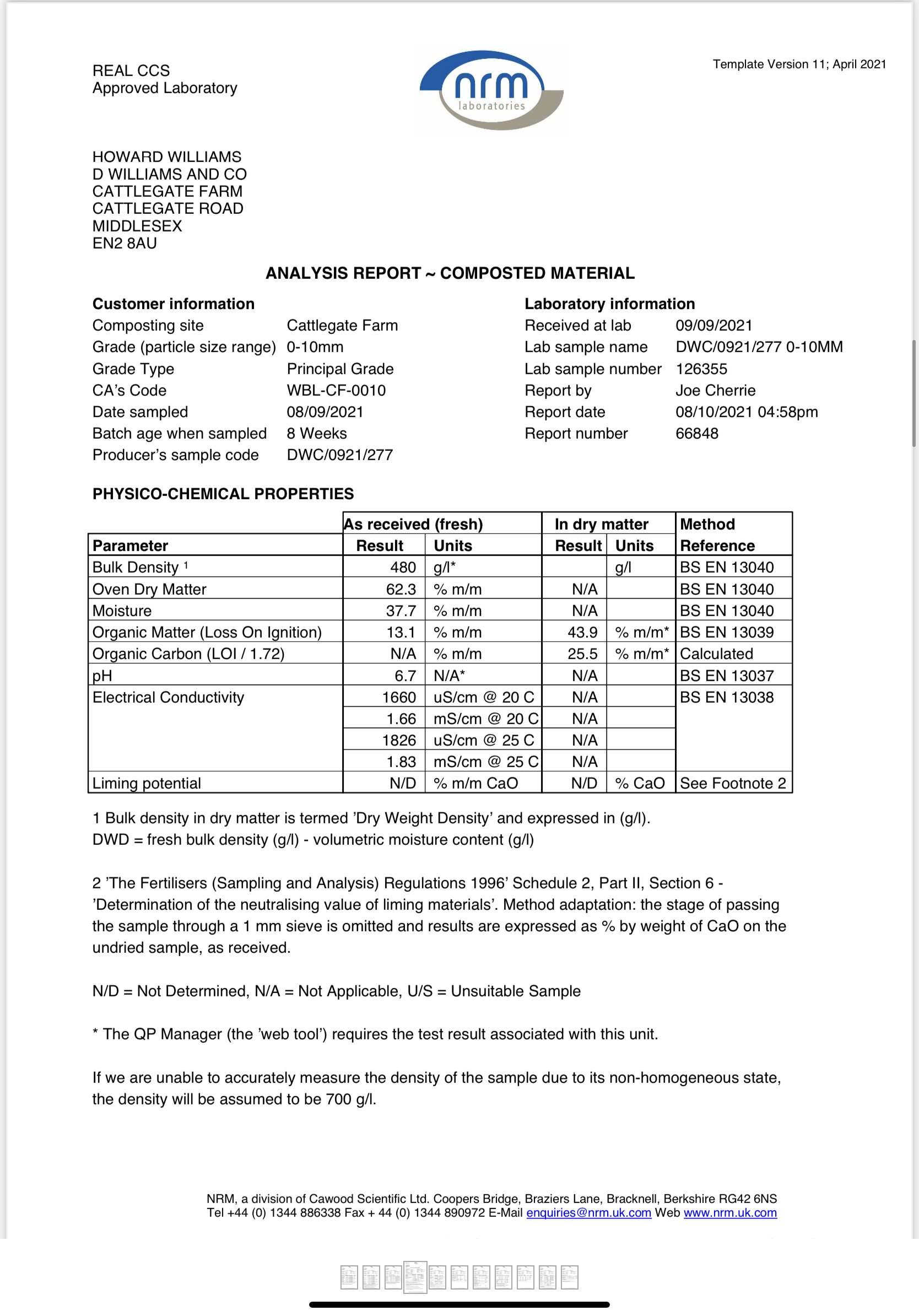

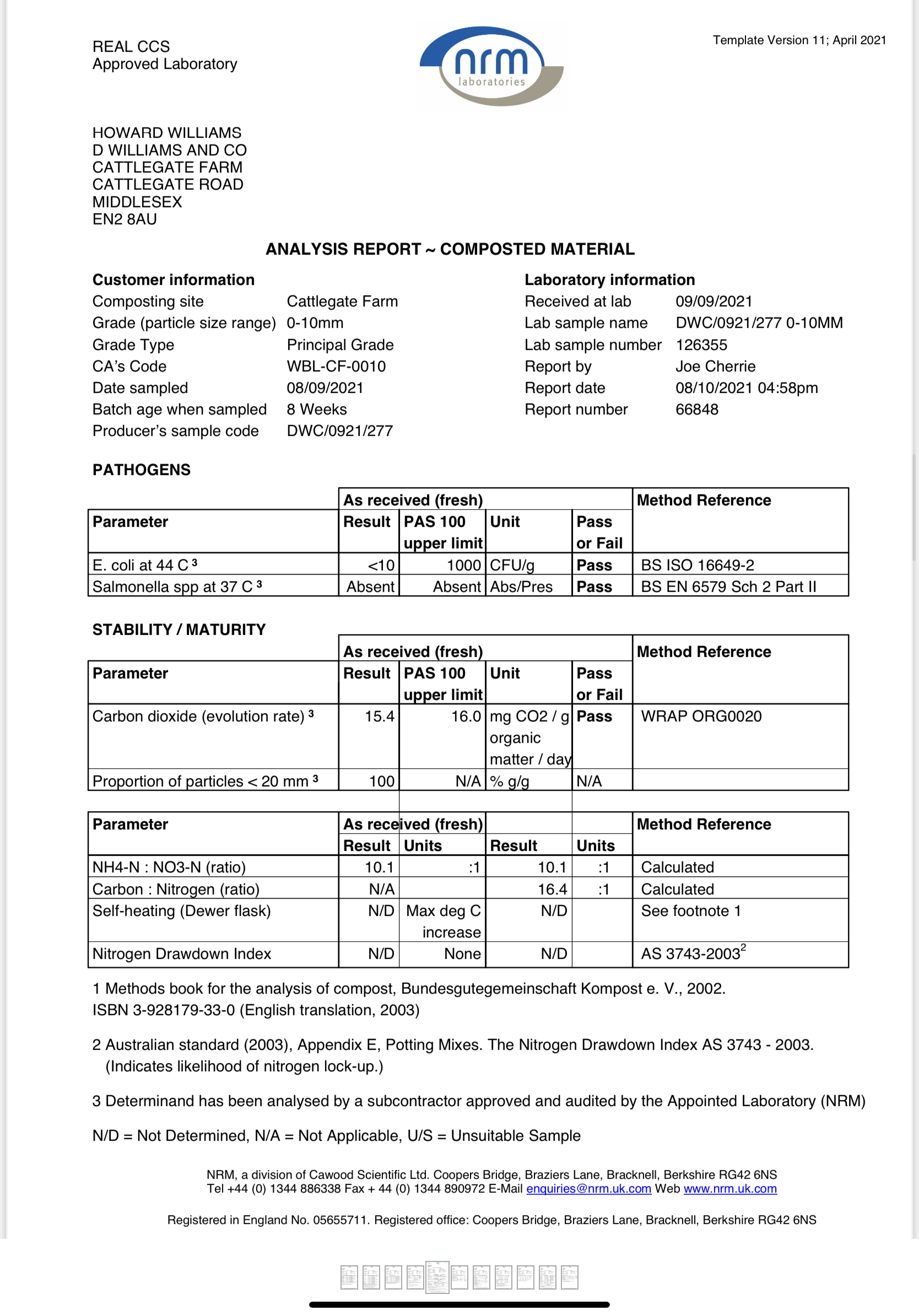

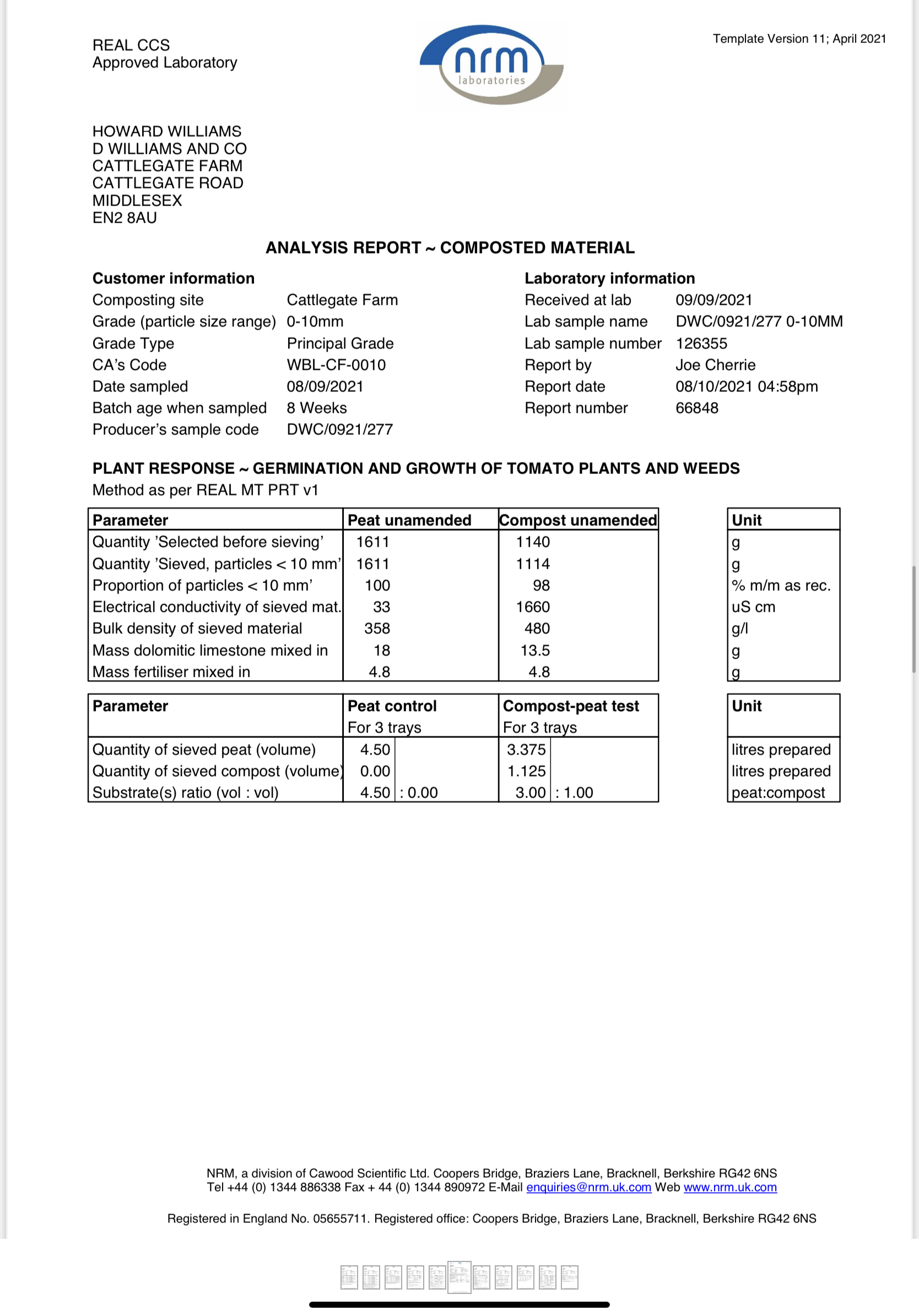

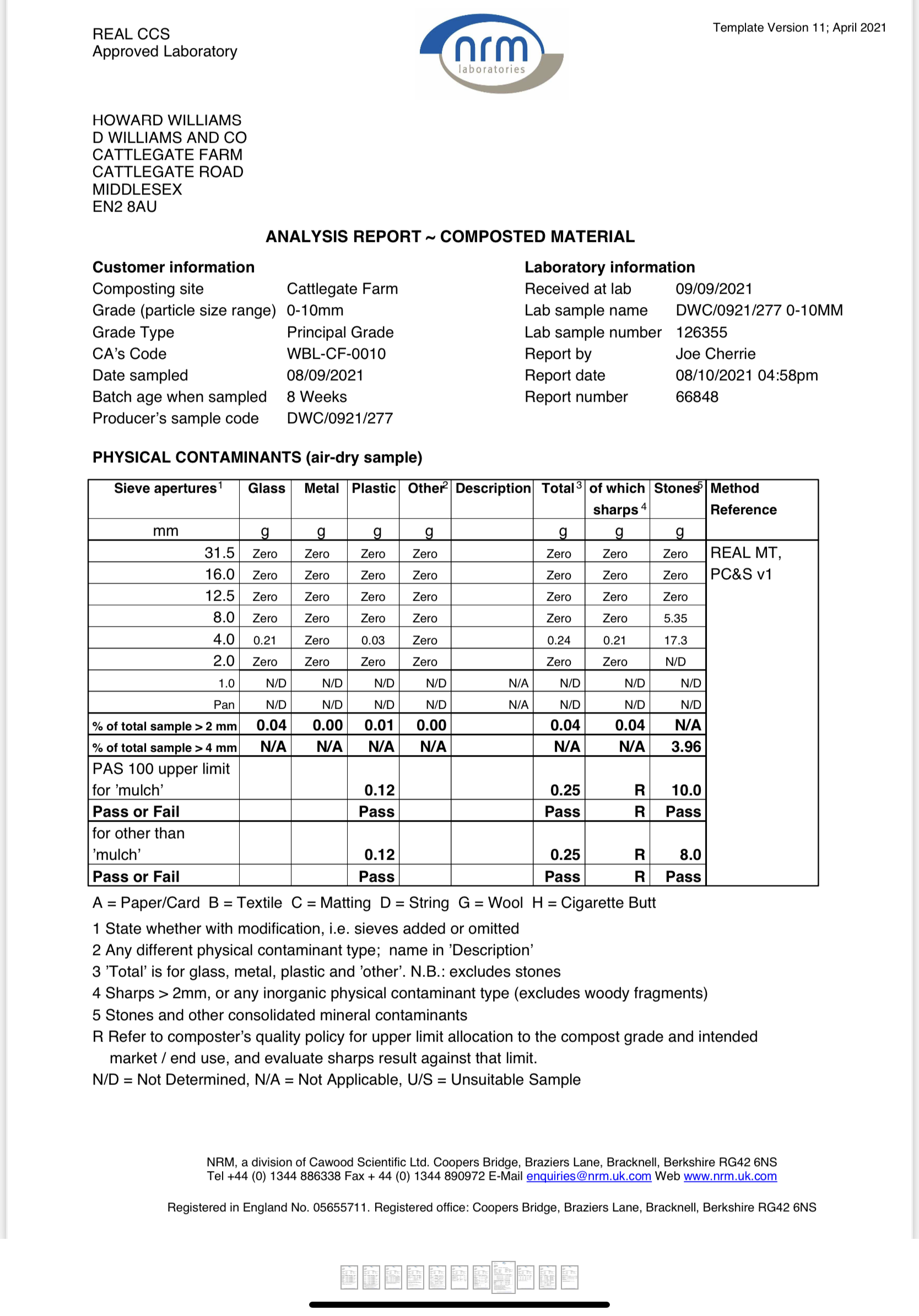

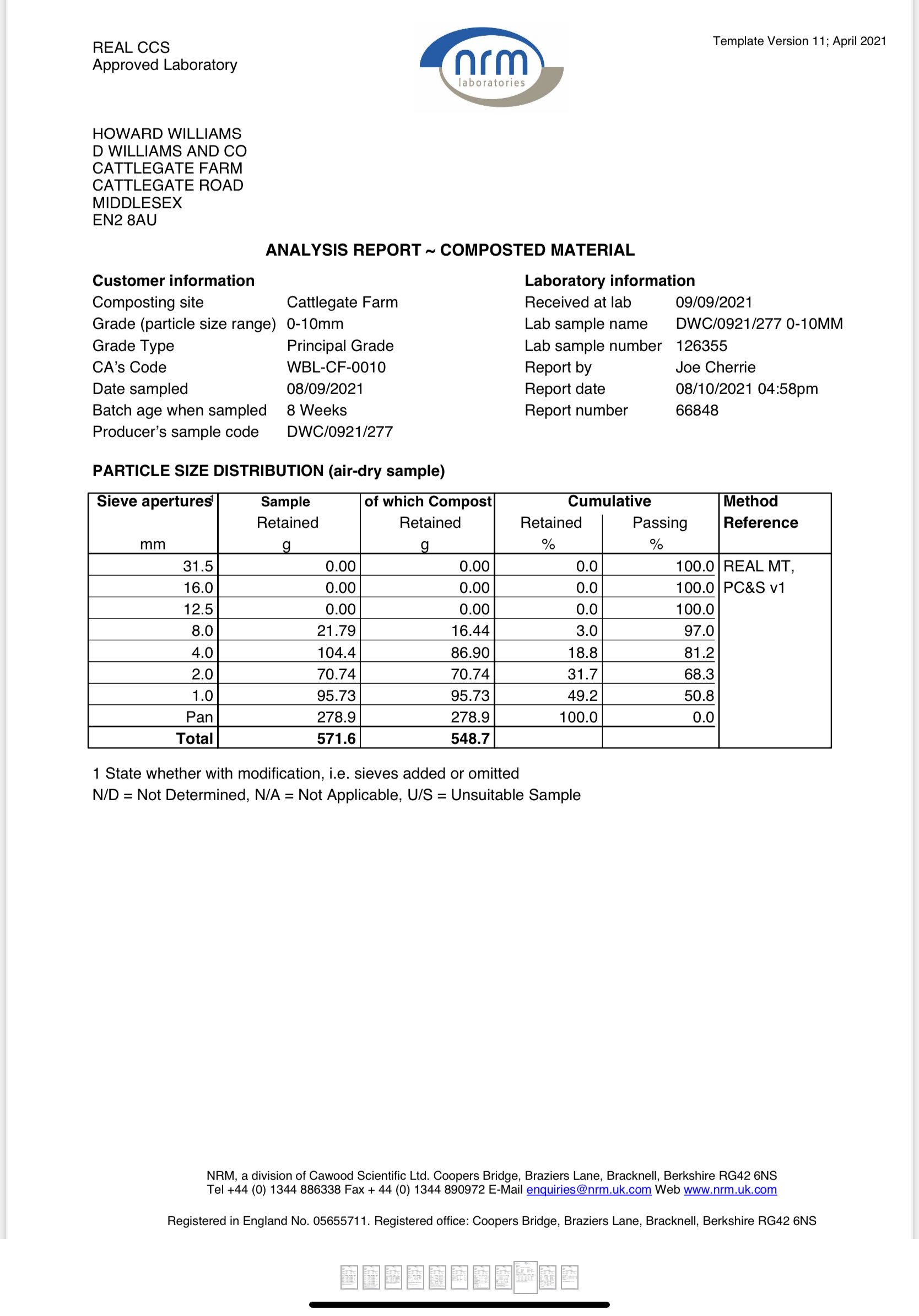

How our organic green compost is made

Our organic green compost is composted of green vegetation from council transfer stations and amenity sites, which is then brought to our farm, shredded into 70mm pieces, and put into windrows. The windrows are then monitored daily for temperature, Oxygen, Carbon Dioxide, and moisture levels. The windrows are turned on a weekly basis, which helps to mix the compost and most importantly introduces more oxygen into the windrow.

After 7 to 8 weeks the compost is put through a screening machine, extracting the 30mm product and 10 mm compost fines ready to use.

But why use Equigrow products?

Using Equigrow products is beneficial for everyone (including the environment) because our products are completely NATURAL and PEAT FREE!! We add no harmful chemicals when composting, we like to use our own tried and tested methods. We make sure our windrows reach temperatures of 50°c – 55°c for 10 – 15 days. Therefor killing any pathogens in the compost, this means that no stray weeds will be present. The process takes 10-12 weeks with regular turning to aerate the windrows. However, in dry spells we will add water to help the process.

Still have questions?

Hopefully you’ve found everything you need, but if you have any further questions or queries, then please get in touch with us.

Meet the team behind all of the operations at Equigrow HQ…

From left to right meet, Michael looks after the composting process of the horse manure, Maria who specialises in orders and admin, Gary who picks up and delivers the horse manure from local farms, Adrian is a Director, Allan who is also a director, Allana specialises in social media and admin, Tony is our friendly delivery driver, Tamâs works on the production line!

We are one big friendly team who strives our best to give you the finest quality compost around the UK.

The Equigrow Process

Here is a video showing you the process the compost goes through before reaching your door steps. Firstly, the manure is picked up from farm yards across the UK, it is then brought back to Cattlegate Farm in Enfield where it is tipped and turned regularly which allows oxygen to permeate through; creating heat which therefore kills any weed seeds and pathogens. After roughly a month, the manure is put through a shredder to help break it down, therefore speeding up the process. For the next three months, the manure is continued to be turned and lastly it is bagged up ready for distribution.

Proud to have supplied…

View our certificates here

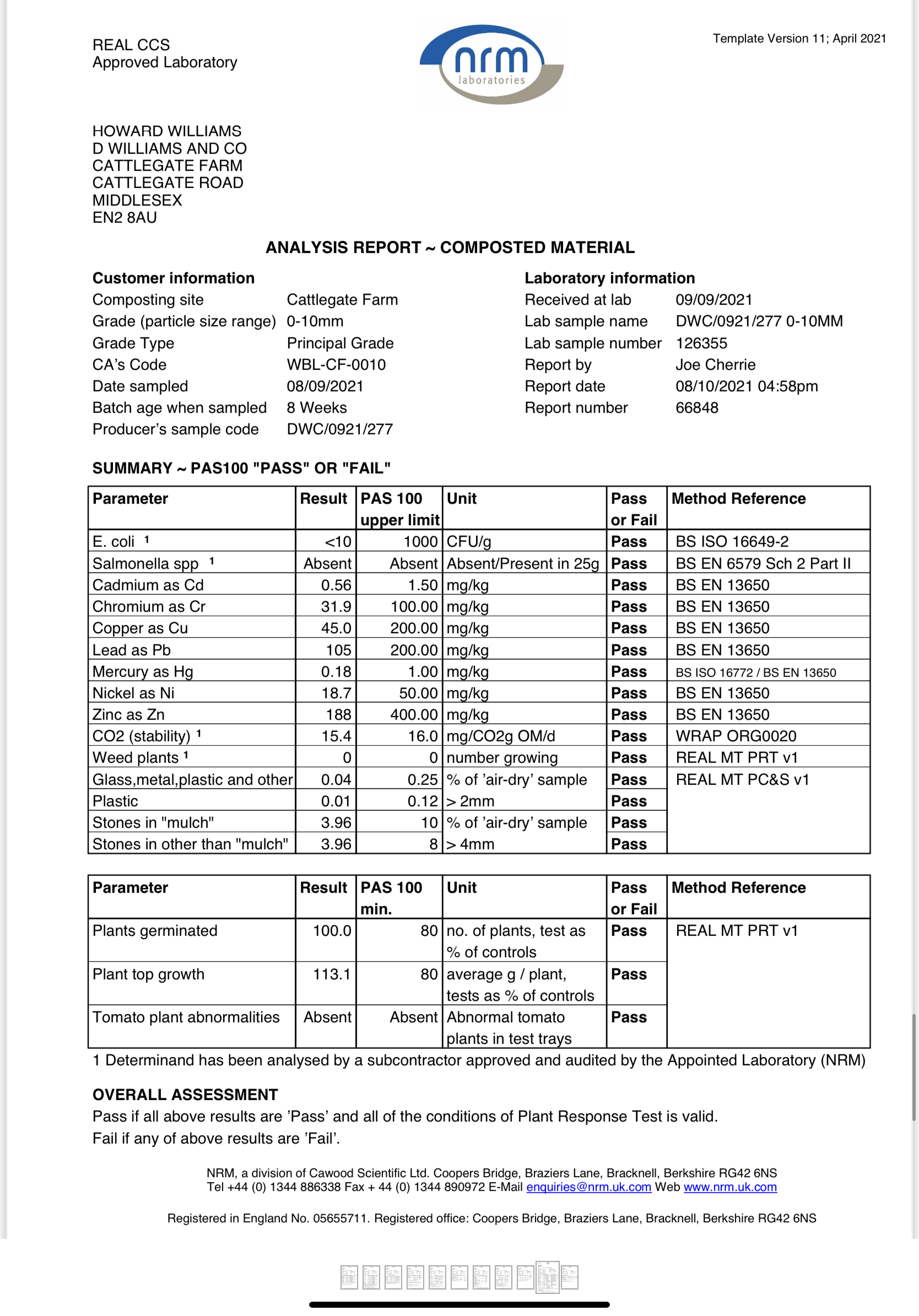

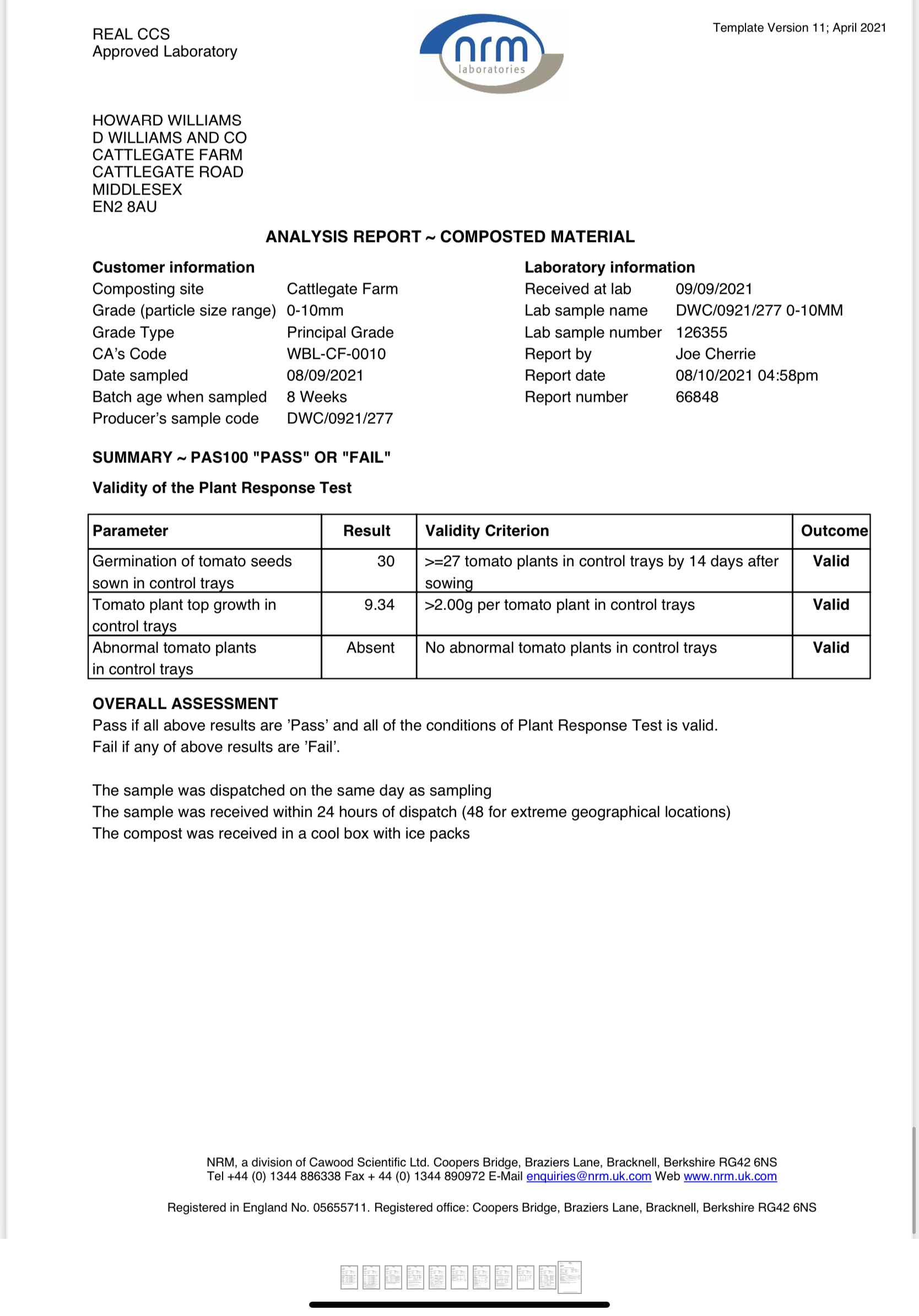

PAS100

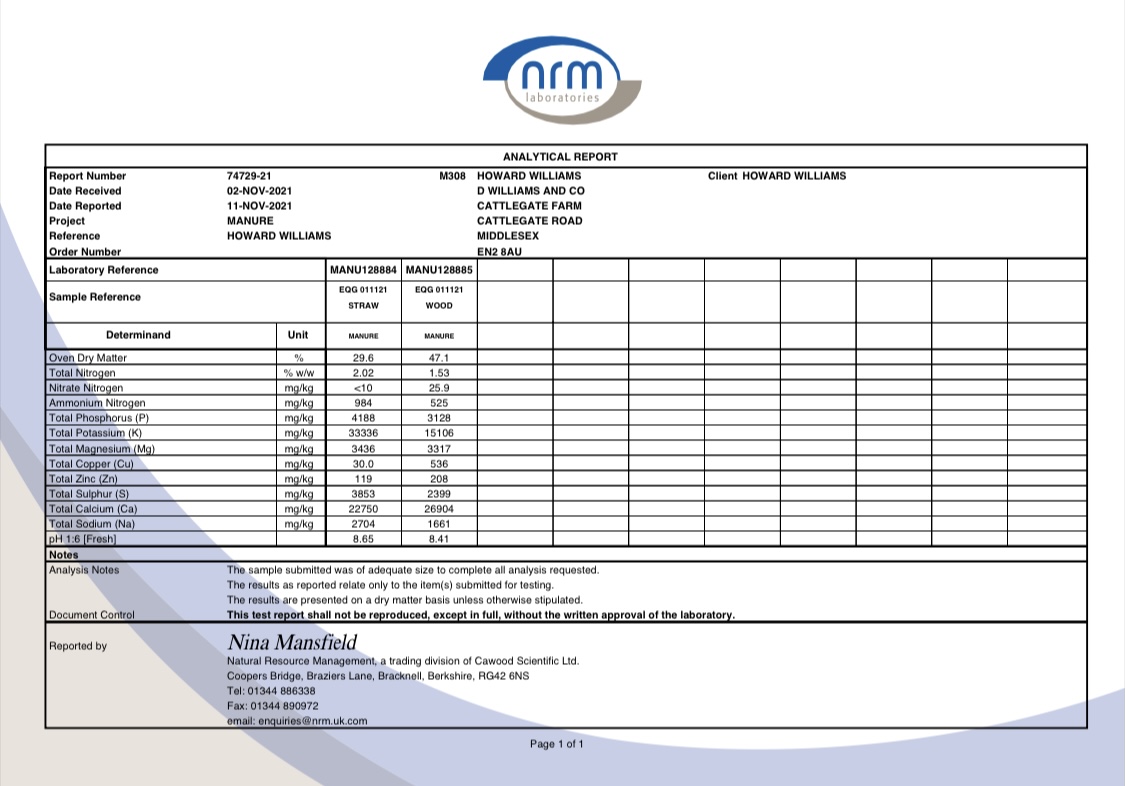

Straw-Based

Shavings-Based